Unlock the Power of Full-Body Strength Training at Home

Introduction:

In today’s fast-paced world, finding time to hit the gym can be a challenge. However, with the rise of home fitness trends, you can now harness the power of full-body strength training right in the comfort of your own home. Let’s delve into how you can transform your fitness routine with effective home workouts targeting every muscle group.

Maximize Your Workout Efficiency:

One of the key benefits of full-body strength training at home is its efficiency. Rather than targeting isolated muscle groups on separate days, full-body workouts allow you to engage multiple muscle groups in a single session. This means you can achieve significant results in less time, making it ideal for busy individuals juggling work, family, and other commitments.

Elevate Your Strength and Endurance:

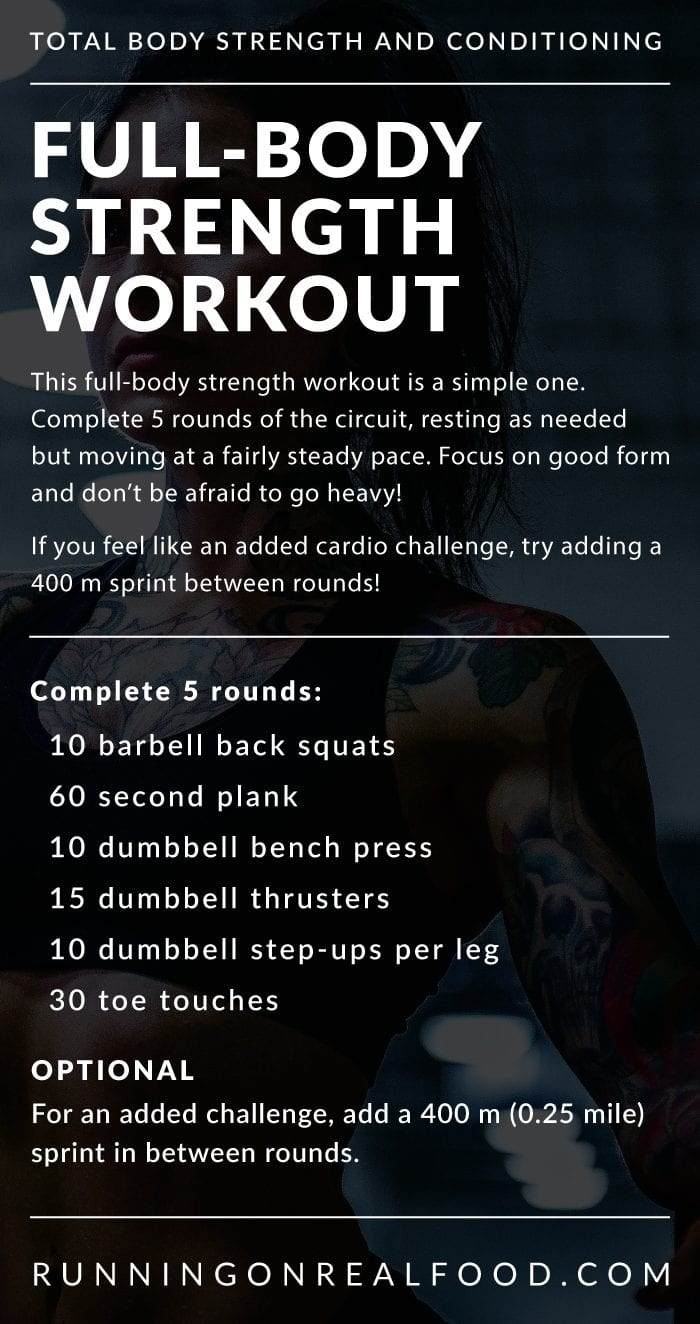

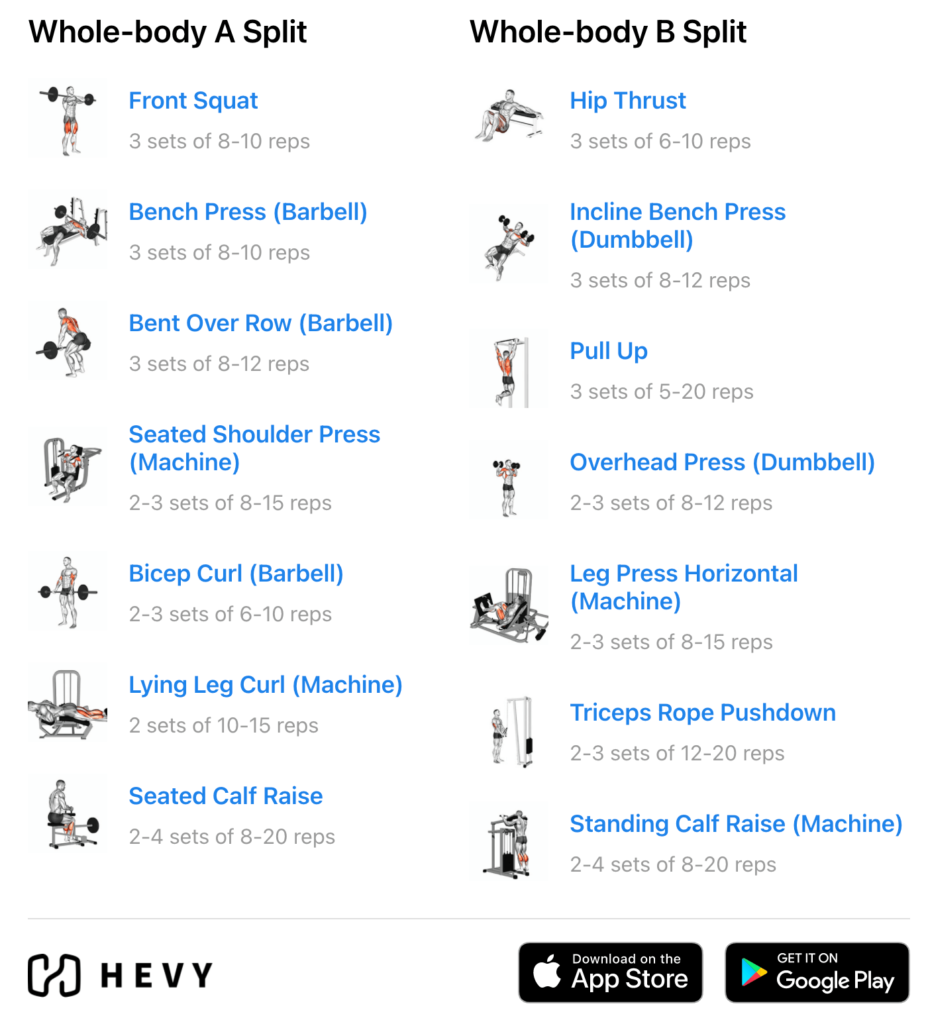

By incorporating compound exercises such as squats, deadlifts, lunges, and presses, home-based full-body strength training workouts help you build functional strength and endurance. These movements not only target major muscle groups but also improve overall coordination, balance, and stability, translating to better performance in everyday activities and sports.

Customize Your Workout Regimen:

One of the beauties of home-based full-body strength training is its adaptability. Whether you’re a beginner looking to establish a foundation of strength or an experienced lifter aiming to push your limits, you can tailor your workout regimen to suit your fitness level and goals. From adjusting weights and repetitions to modifying exercises and rest intervals, the flexibility of home workouts allows for endless variations and progressions.

Invest in Basic Equipment:

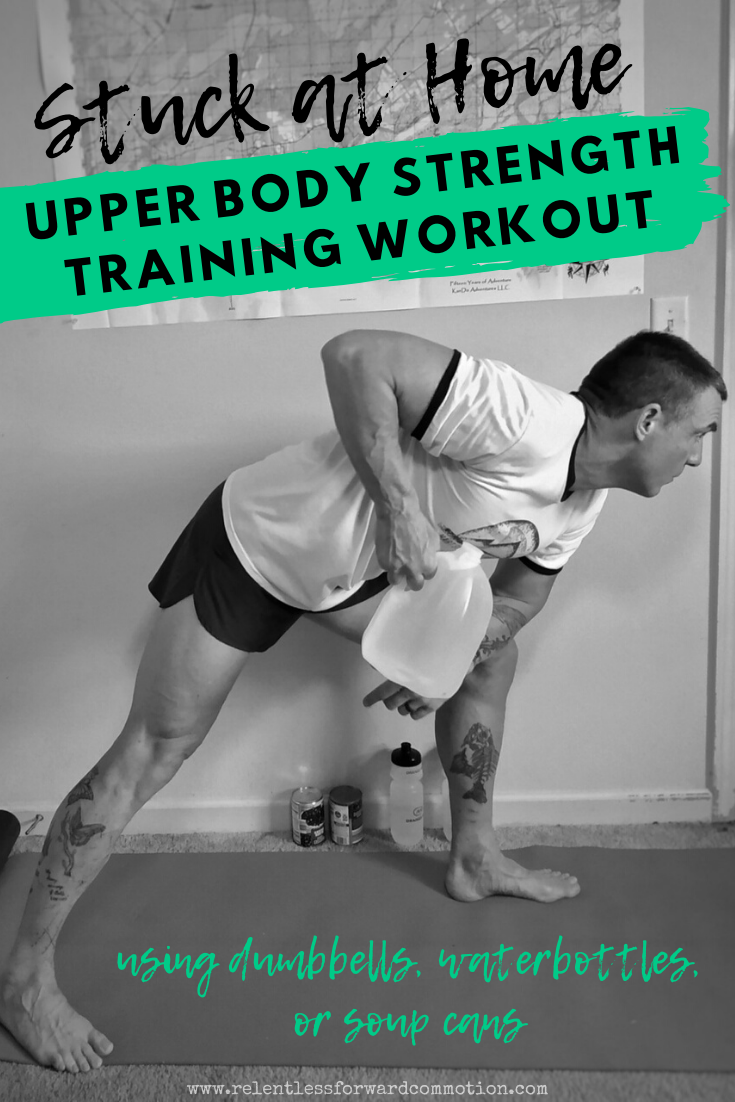

While some full-body strength training exercises can be performed using just your body weight, investing in basic equipment can enhance your home workout experience. Consider purchasing a set of dumbbells, resistance bands, a stability ball, or a kettlebell to add resistance and variety to your exercises. These versatile tools can help you target different muscle groups and achieve a well-rounded workout.

Create a Dedicated Workout Space:

To maximize your focus and motivation during home workouts, designate a dedicated space for exercise within your home. This could be a spare room, a corner of your living room, or even your backyard. Ensure the space is free from distractions and equipped with the necessary equipment and amenities to support your workout routine.

Stay Consistent and Motivated:

Consistency is key when it comes to seeing results from your home-based full-body strength training workouts. Establish a regular workout schedule and stick to it, treating your exercise sessions with the same commitment as you would a gym appointment. Set realistic goals, track your progress, and celebrate your achievements along the way to stay motivated and inspired on your fitness journey.

Incorporate Variety and Progression:

To prevent boredom and plateauing, it’s important to incorporate variety and progression into your home workout routine. Mix up your exercises, change your rep ranges, and challenge yourself with new movements to keep your muscles guessing and continuously adapt and improve. Gradually increase the intensity of your workouts over time to ensure progressive

:max_bytes(150000):strip_icc()/3-SquatOverheadPress-56fac9d75f9b58298673683c.jpg)